SERVICES

Engine Rebuilds

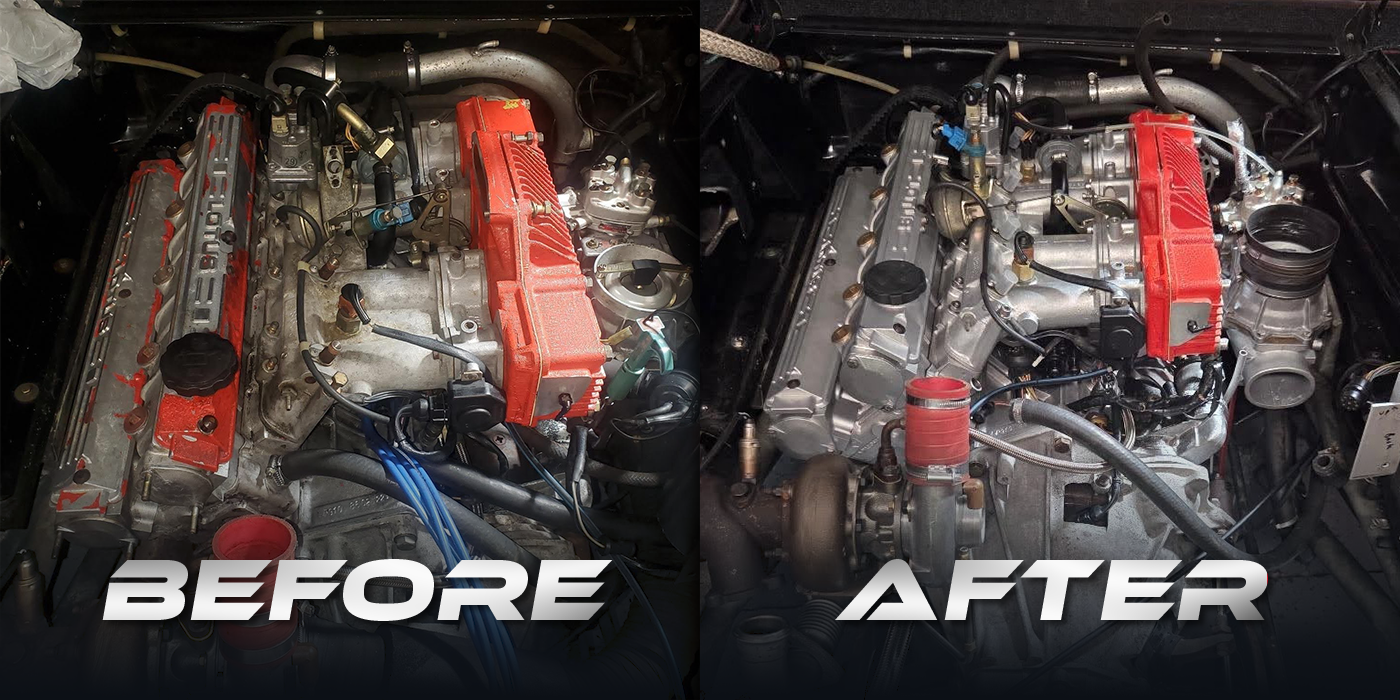

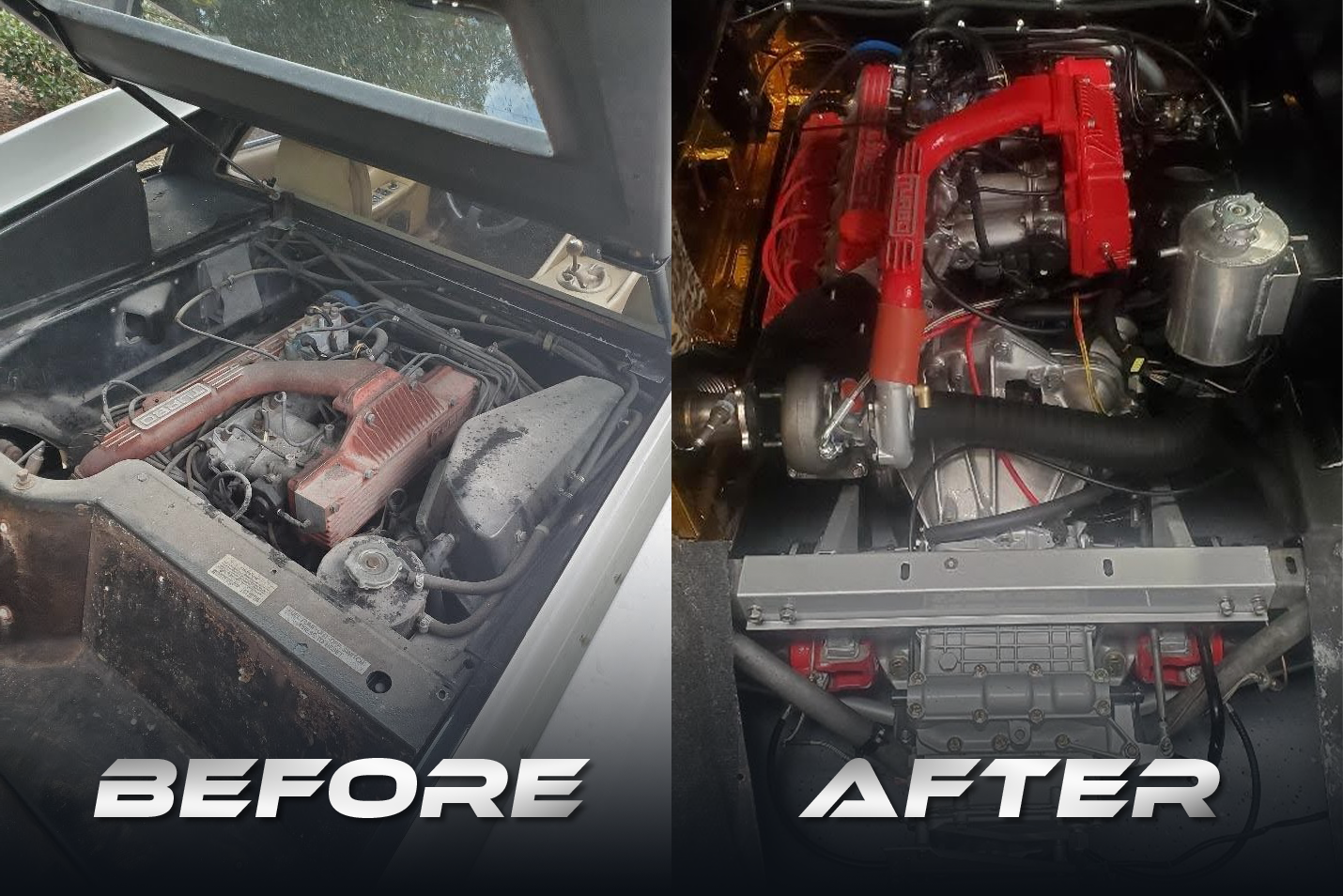

Engines That Run & Look Better Than New

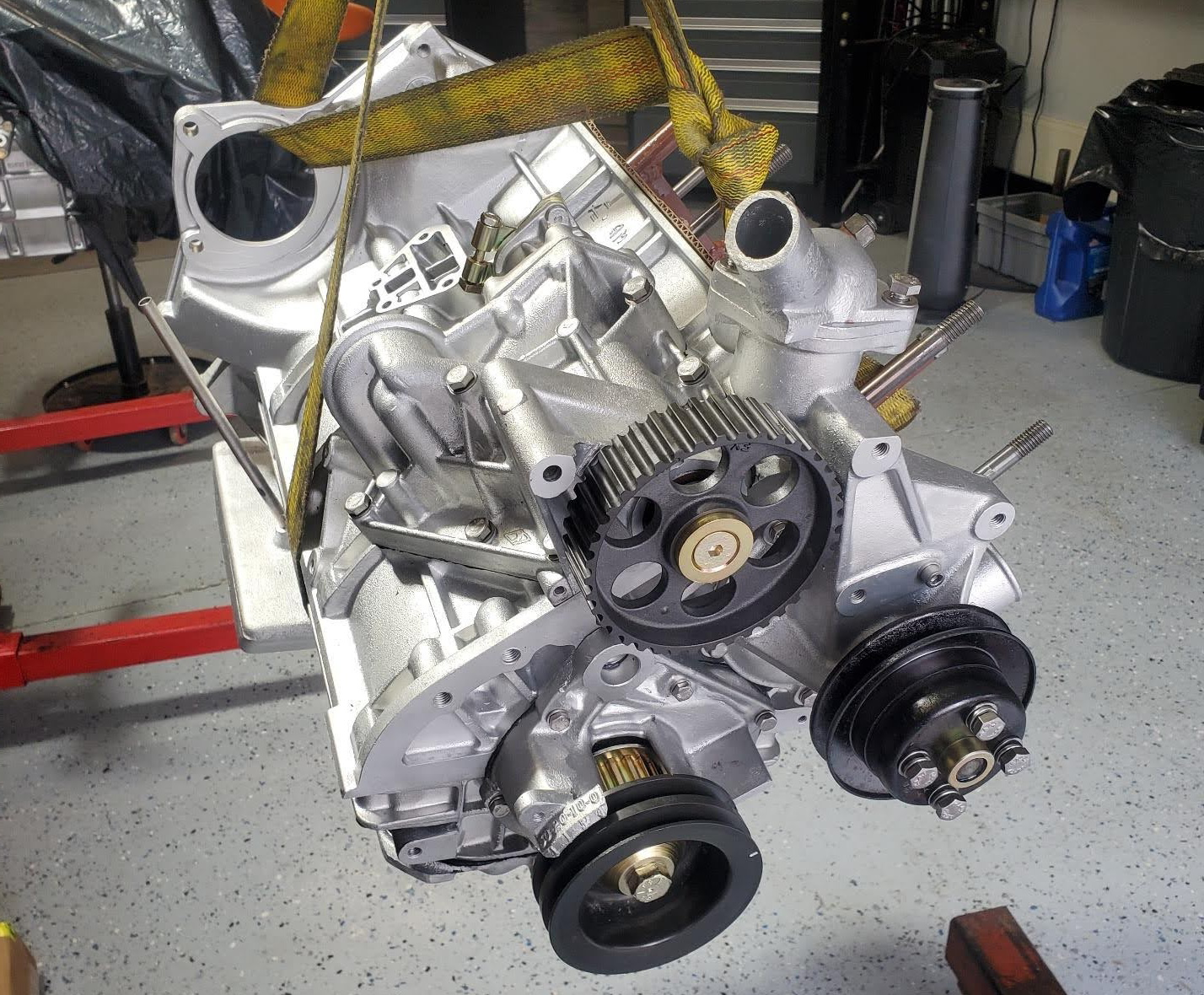

Every West-Cam rebuild begins with a simple goal — to return your Lotus engine to better-than-new condition in both performance and presentation. Each engine is completely disassembled, cataloged, and cleaned to reveal every detail. Aluminum components are vapor-blasted to a uniform satin finish, steel parts are zinc-plated, and all fasteners are restored or replaced.

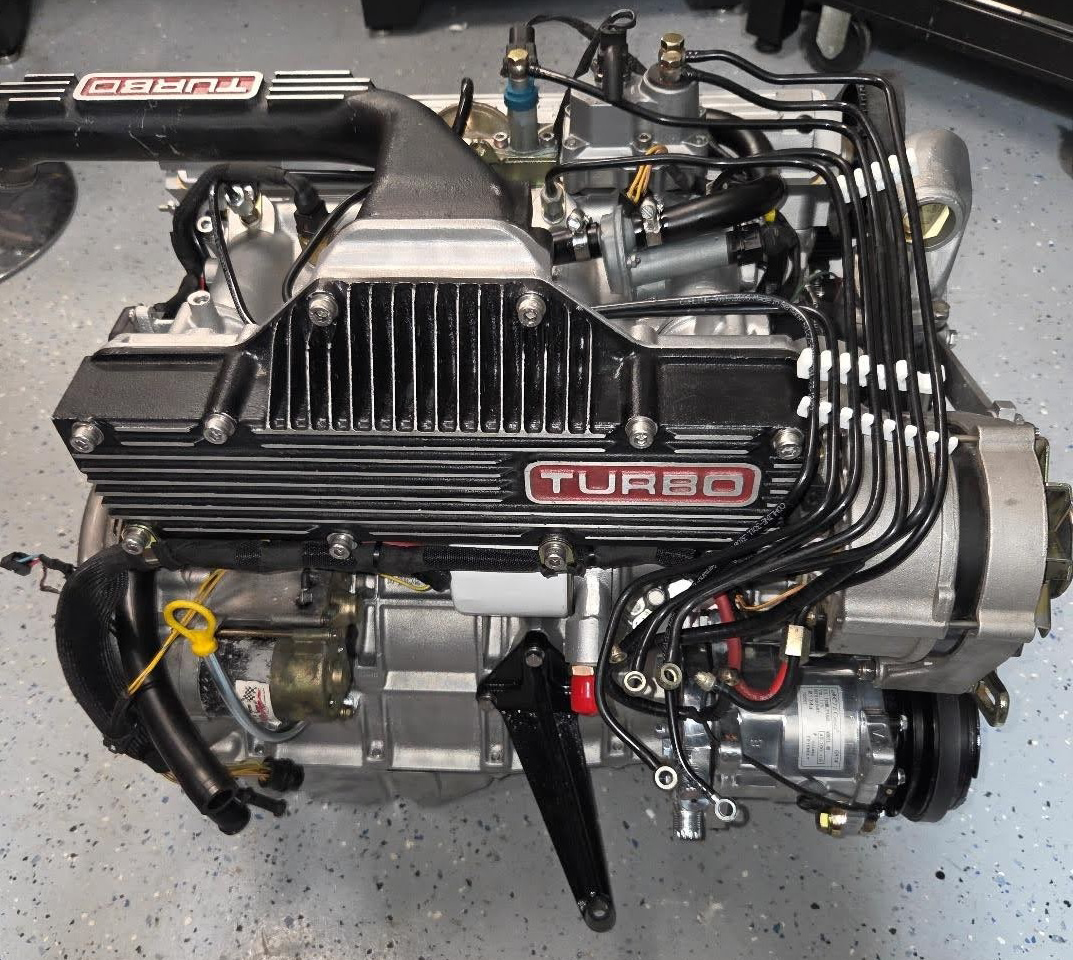

We specialize in Lotus Esprit 907, 910, and 912 engines, along with Elan and Europa Twin Cam engines. Whether your engine arrives complete or in need of missing parts, it’s methodically rebuilt and precision-measured throughout the process. The result is a blueprint-level engine that looks as exceptional as it performs.

Blueprinting Philosophy

A West-Cam rebuild isn’t just a restoration — it’s a re-engineering of the original design intent. Every engine is carefully disassembled and cataloged, each component measured, inspected, and photographed before cleaning begins. This ensures nothing is overlooked and that missing or worn parts are identified early.

All aluminum castings and housings are vapor-blasted to remove corrosion and restore the factory surface texture. Steel brackets and linkages are zinc-plated for lasting protection and a uniform appearance. Once clean, every part is evaluated for wear, reusability, and appearance before assembly ever begins.

During blueprinting, the rotating and reciprocating assemblies are balanced — the crankshaft, flywheel, and pressure plate are matched as a system to ensure smoothness throughout the rev range. Bearing clearances are set within factory specifications using precision instruments, optimizing oil film thickness for both reliability and performance. The goal isn’t simply to make the engine run again. It’s to make it run exactly as Lotus intended — or better.

The Process: From Arrival To Perfection

Every engine that comes through our doors begins with documentation. We photograph the engine as received and record all identifying numbers and details. This ensures traceability and lets customers see the full transformation from start to finish.

Once disassembled, all components are ultrasonically cleaned, vapor-blasted, and plated or refinished as appropriate. Any machining work — from cylinder honing to crankshaft grinding — is carried out by a trusted machine shop familiar with Lotus specifications. We review all measurements before parts ever return for assembly.

Back in our clean assembly area, each step is performed methodically. Crankshaft end float, liner nip, and bearing clearances are verified to Lotus standards. Piston ring gaps and cam timing are optimized for both performance and longevity. Fasteners are torqued precisely, and all visible components are oriented for both mechanical correctness and presentation.

Before completion, every engine is tested and inspected under pressure to verify oil flow, sealing, and compression. Only after it passes inspection is it detailed, labeled, and prepared for installation or shipping.

From the moment it arrives to the day it leaves, each engine follows the same disciplined, repeatable process — blending engineering precision with an obsession for presentation.

Finishes & Customization

Every West-Cam engine is rebuilt to meet or exceed original specifications — but many owners choose to incorporate subtle refinements that enhance reliability and presentation while preserving the authentic Lotus character.

Our OEM-plus options include:

- Forged pistons for improved strength and thermal stability

- New cylinder liners for long-term reliability

- Optimized camshaft timing for refined performance

- Bosch alternator conversions for modern charging efficiency

- Exterior hardware upgrades, replacing all visible fasteners with either stainless steel or yellow zinc-plated bolts, depending on your preferred appearance

All engine blocks remain bare aluminum, carefully vapor-blasted to a uniform satin finish that highlights the casting detail. Components originally finished by Lotus — such as cam covers, diffusers, and plenum chambers — can be professionally repainted in the correct factory color and sheen.

Every build is a collaboration. Whether you prefer an untouched factory look or a concours-level finish, we treat each part as a piece of mechanical art — restored with precision, accuracy, and care.

Testing & Results

Before an engine leaves West-Cam, it must first prove itself. Every build undergoes a detailed inspection and a series of validation checks to confirm oil pressure, sealing integrity, and mechanical balance.

Each engine is pre-lubed and pressure-tested to verify correct oil flow through all galleries and bearings. Compression and leak-down tests confirm proper sealing of the combustion chambers and valve seats. We also check all external fittings, lines, and seals to ensure the engine is leak-free and ready for installation.

Engines are rotated and run through their initial cycles while monitoring for smooth operation, correct cam timing, and even oil distribution. Only after it passes every inspection is it detailed, labeled, and prepared for delivery.

The result is more than a restored powerplant — it’s a precision-verified, show-quality engine that’s ready to install and enjoy with confidence.

The Customer Experience

A West-Cam engine rebuild is a partnership. We keep every customer connected to their project from start to finish, with weekly progress updates, photos, and videos that document the entire process. You’ll see each phase — from teardown to final assembly — so you always know exactly where your engine stands.

We encourage owners to be as involved as they wish. Some prefer to follow along quietly, while others enjoy discussing details like cam cover color, hardware finish, or carburetor setup along the way. Either approach is welcome.

Our goal is complete transparency and confidence. When your engine is finished, you’ll not only receive a powerplant that meets factory specifications — you’ll understand the craftsmanship that went into every part of it.

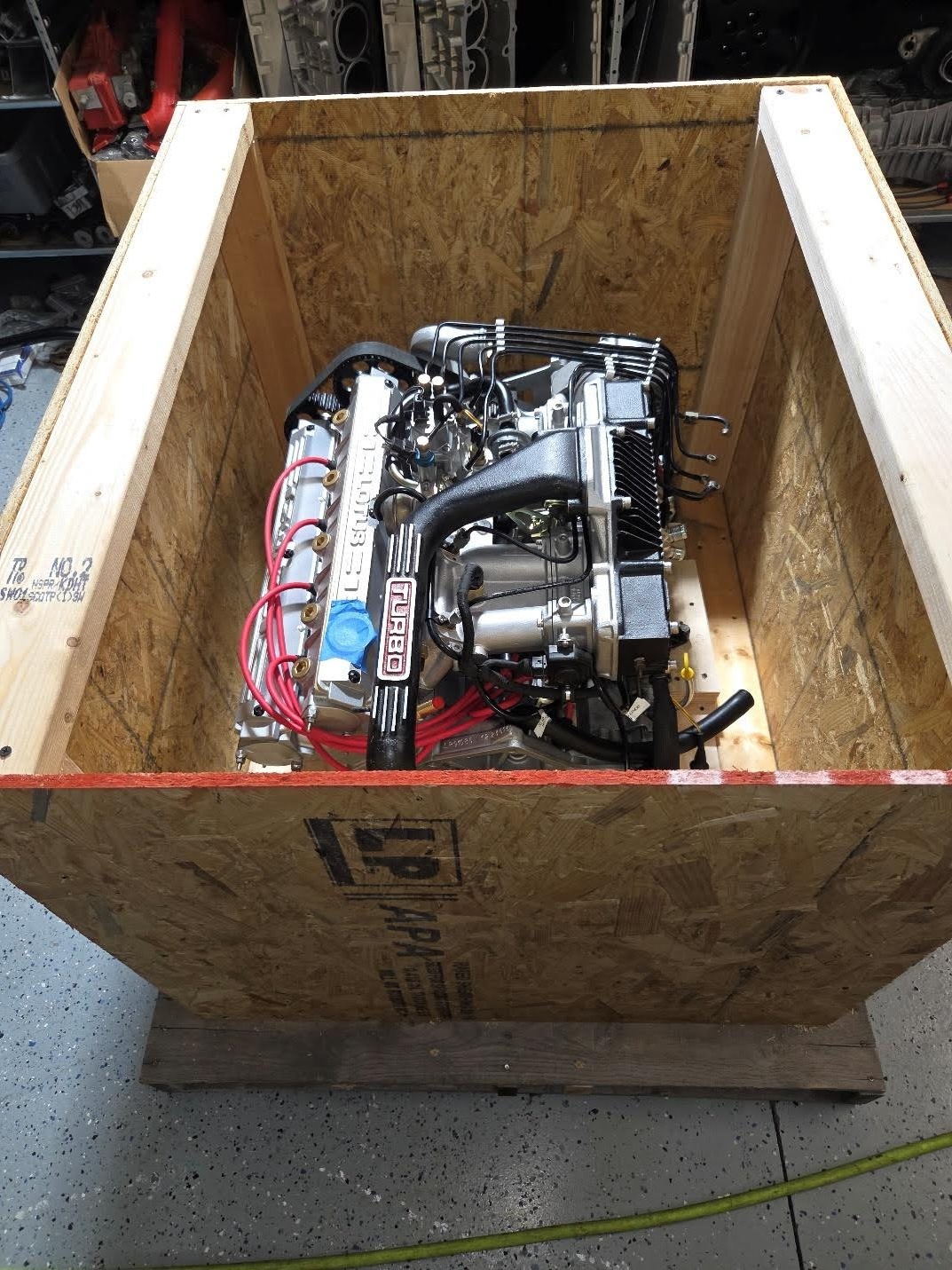

Nationwide Shipping

Engines can be shipped to and from West-Cam from anywhere in the United States. We build custom wooden crates for every project, designed to securely support and protect the engine during transit. Each crate is fitted with reinforced mounting points and internal blocking to prevent any movement or vibration.

Engines are carefully wrapped and secured before shipment, and we coordinate with trusted freight carriers experienced in handling valuable automotive components. Upon arrival, engines are fully documented and inspected before any work begins.

Whether you’re shipping from a few miles away or across the country, you can trust that your Lotus engine will arrive safely and be treated with the same care and precision it receives throughout the rebuild.

Ready To Begin Your Engine Rebuild?

If you’re ready to bring your Lotus engine back to its best, let’s talk. Whether you’re restoring an Esprit, Elan, or Europa, we’ll treat your engine as if it were our own — with precision, craftsmanship, and the respect it deserves.